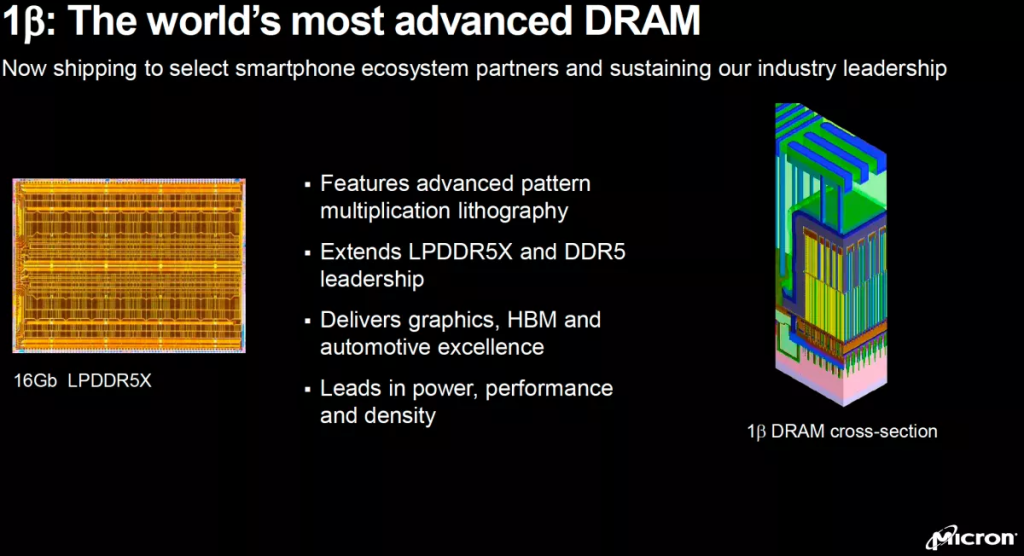

Micron has introduced its latest generation 1β (1-beta) DRAM (dynamic random access memory) fabrication. Micron will be able to reduce DRAM costs while enhancing power efficiency and performance thanks to the next node. The company’s final way to make DRAM chips will use deep ultraviolet (DUV) lithography instead of extreme ultraviolet (EUV) technologies.

Micron DRAM technology With 1β Node

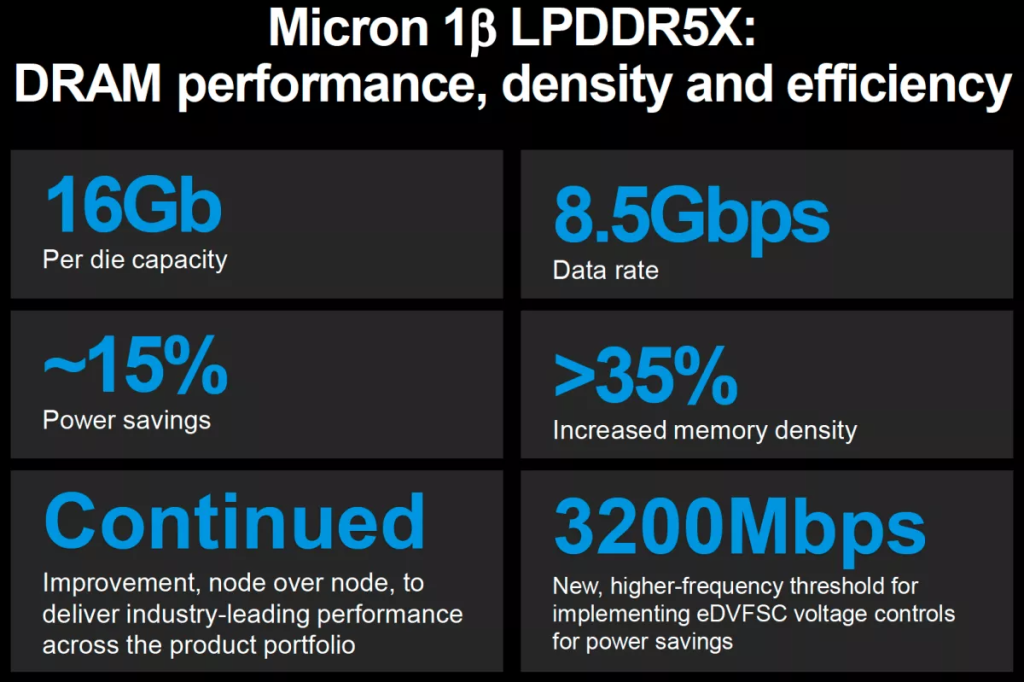

Its low-power double data rate 5X (LPDDR5X) mobile memory technology offers high performance levels of 8.5 gigabits per second. The node offers big improvements in performance, bit density, and power efficiency, which will be good for a wide range of markets.

- Beyond smartphones and tablets, 1β (1-beta) offers the low-latency, low-power, high-performance DRAM needed to support highly responsive applications, real-time services, and the contextualization and personalization of experiences across intelligent vehicles and data centers.

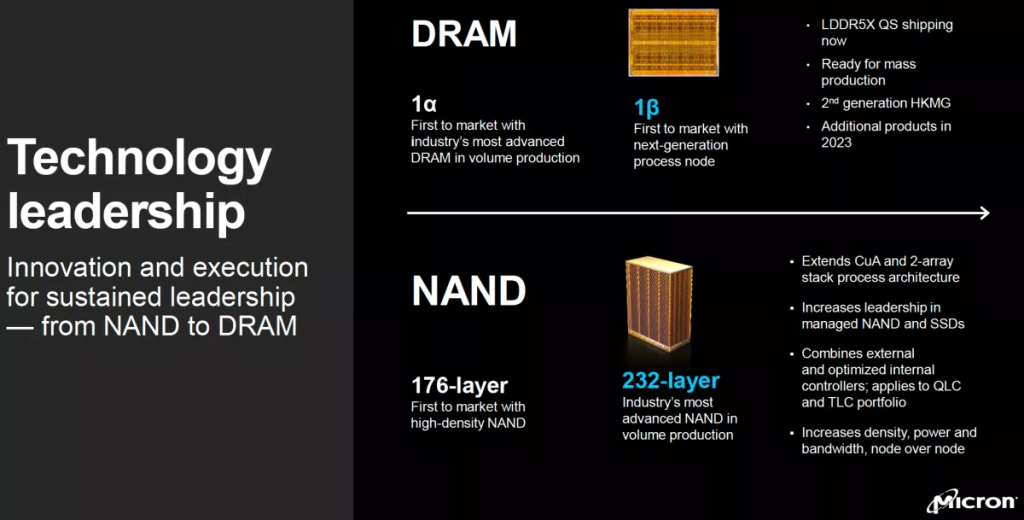

- Also, 1β (1-beta) is a step forward for the company’s market leadership, which will be strengthened when 1α node is shipped in large quantities in 2021.

- With a 16Gb per die capacity, the node improves power efficiency by roughly 15% and bit density by more than 35%.

Micron’s first product to use its cutting-edge node will be 16Gb LPDDR5X-8500 memory, but the company will eventually use the node for other products. The chip’s 16Gb of LPDDR5X memory is stated to have enhanced dynamic voltage and frequency scaling extensions core (eDVFSC) voltage control algorithms for power savings.

Micron 1β LPDDR5X

LPDDR5X memory was created not just for mobile applications such as tablets and smartphones, but to boost the performance of other bandwidth-hungry applications such as PC-class system-on-chips and AI accelerators.

According to Micron, its 16Gb LPDDR5X-8500 memory and 1β manufacturing technique are ready for mass production. Currently, the company is distributing samples of its LPDDR5X-8500 DRAMs to willing parties and will begin mass manufacturing of these ICs after qualification procedures are completed.

Micron has aggressively enhanced its manufacturing expertise, technical capabilities, and pioneering R&D over the last many years to establish a competitive edge with 1β and 1α.

This faster innovation enabled Micron to launch its 1α node one year ahead of the competition, establishing Micron’s leadership in DRAM and NAND for the first time in the company’s history.

Micron has also invested billions of dollars in converting its fabs into cutting-edge, highly automated, sustainable, and AI-driven facilities over the years. This includes investments in Micron’s Hiroshima, Japan, facility, which will begin mass production of DRAM on 1β.

Availability

It is now sampling 1β DRAM to mobile ecosystem. The business will start ramping up the remainder of its portfolio on 1β over the course of the upcoming year across the embedded, data centre, client, consumer, industrial, and automotive industries, including graphics memory, high-bandwidth memory, and more.

Speaking on the announcement, Scott DeBoer, Executive Vice President of Technology and Products at Micron, said,

The launch of our 1-beta DRAM signals yet another leap forward for memory innovation, brought to life by our proprietary multi-patterning lithography in combination with leading-edge process technology and advanced materials capabilities.

In delivering the world’s most advanced DRAM technology with more bits per memory wafer than ever before, this node lays the foundation to usher in a new generation of data-rich, intelligent and energy-efficient technologies from the edge to the cloud.